STAR*PAC® Stages

Learn More about the Advantages of Using Star*Pac® for Plant Micropropagation

Garner US Enterprises, Inc. in Willis, Texas, is your source for polyethylene bags for plant micropropagation. Read our complete report to understand the advantages of using the Star*Pac® system.

Star*Pac™ Versus Conventional Means

This report outlines the key differences, advantages, and cost savings when using the AgriStar patented Star*Pac® system for plant micropropagation as opposed to conventional systems utilizing glass or rigid plastic containers. The report is divided into the various stages of plant tissue culture.

Stage I

In conventional systems, Stage I material is generally started in test tubes due to the high degree of contamination associated with new cultures. Test tubes are somewhat bulky and with the rack used for test tubes take up excess shelf space. Test tubes are either placed upright or on a slant. The slanted system is even less space efficient. If test tubes are stored upright, then a clear cap must be used to allow light to pass to the culture. Test tube caps are loose fitting and should be wrapped with tape or parafilm to reduce the risk of external contaminants. The high degree of contamination in Stage I cultures and the large number of units typically handled in Stage I creates an excessive amount of washing of glassware. Read the full Stage 1.

Stage 2

Conventional systems use either glass baby food jars or rigid plastic containers. Both units employ loose fitting caps. The inherent problem with loose fitting caps is the potential risk of infestation by dust or lab mites. These organisms are very difficult to see and, until they become a serious problem, may go undetected. The problem lies with the movement of the mites from one vessel to another creating contamination of all the units because the mites track bacteria and mold spores from one container to the next. The loose fitting cap also allows for the evaporation of water from the media creating media that becomes more concentrated over time (2 to 3 weeks) and necessitates the transfer of cultures within 6 to 8 weeks. In drier climates this may be even more frequent. Read the full Stage 2 report.

Stage 3

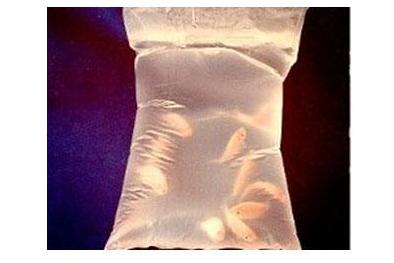

Stage 3 is very similar to stage 2 in many respects. The main difference is that the length of time in culture is frequently much shorter than Stage 2. The risk for contamination is not as great since the cultures are destined for planting outside the lab and are not being used for re-multiplication. When cultures must be shipped in media, as is the case with many international shipments, jars or other rigid walled containers are costly to ship and pose many problems such as media leakage from the container, space inefficiency, and breakage. Read the full Stage 3 report.

Contact us today in Willis, Texas, for more information about how to make plant micropropagation more cost effective.